Demo Day: Robotic Automation of Innovative Spark Erosion (RAISE) – with Scintam Engineering

by Michael Oates

The RAISE (Robotic Automation of Innovative Spark Erosion) project was born from the CRADLE IdEAs (Industry Engagement Activity) process. This was done as a collaboration with startup SME Scintam Engineering who have developed unique portable EDM (Electrical Discharge Machining) equipment – designed for the fast removal of seized fasteners such as bolts or rivets, that may otherwise result in long delays at overhaul. This is a new technology with high value potential to several industries, in particular as part of a roboticised solution to allow for remote operation and automation in demanding and long-lasting environments.

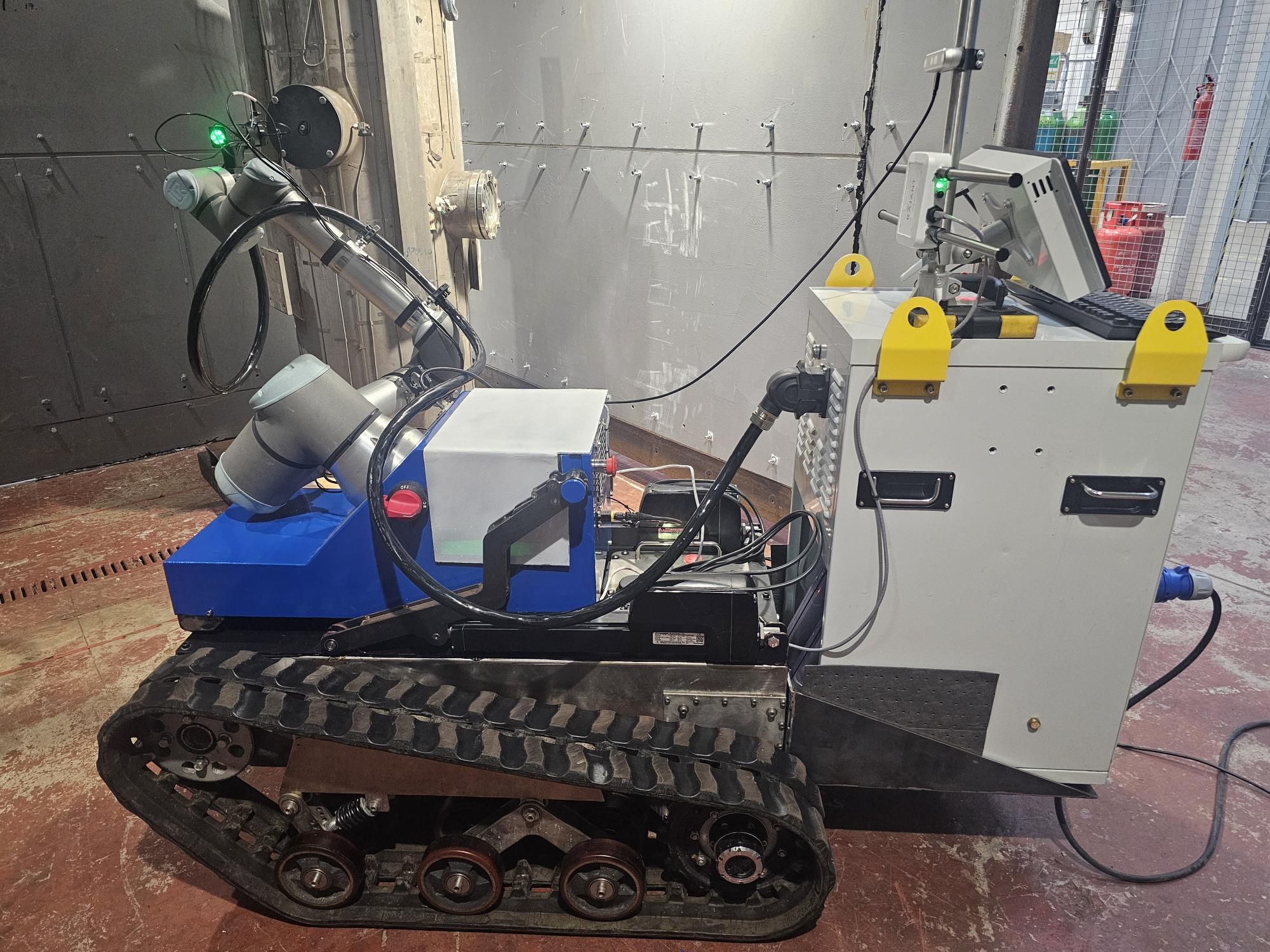

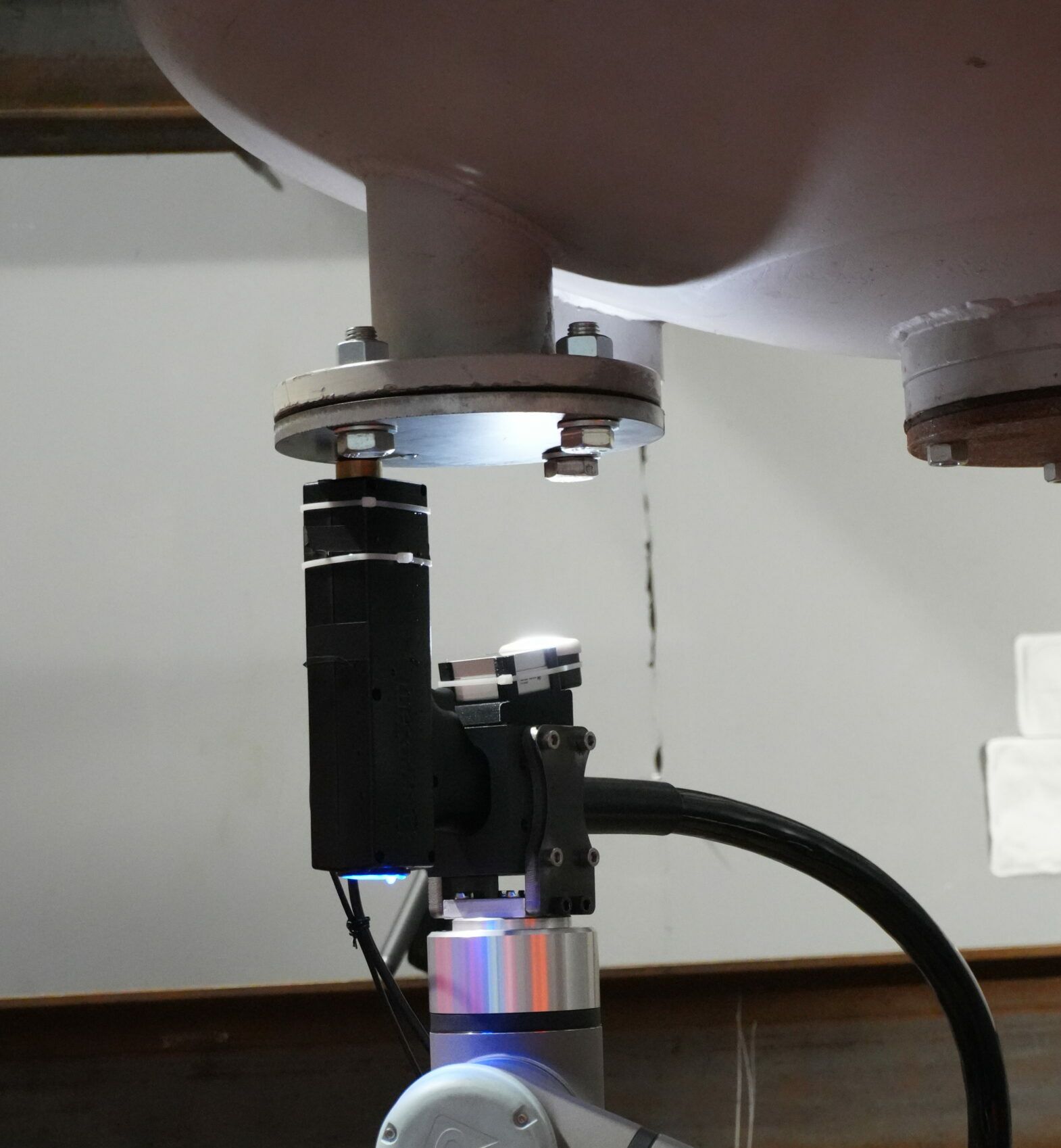

CRADLE led a three-month technical development programme culminating in a live technology demonstration to industry professionals, hosted at the Amentum laboratories in Birchwood. The showcased technology comprises a base X2 tracked robot platform for navigation, with a UR10 manipulator arm to allow for dextrous control of the EDM probe, which is integrated as a payload. The CRADLE team integrated onboard cameras and sensors and developed a control architecture which enabled full remote operation, environment mapping and automated detection of target bolt features for removal. After this initial phase of development, the system is capable of remotely removing fasteners in a mock-up nuclear cell environment, demonstrating potential future value for the nuclear decommissioning industry amongst other potential applications.

CRADLE hosted a technology demonstration day in Birchwood to a number of leading industry professionals, largely from the nuclear industry. There are clear advantages to the application of this technology in a nuclear decommissioning environment, due to the precision, lack of waste material and non-existent reaction forces. Feedback from industry was universally positive, with a clear suggestion that this technology could open up new avenues for the decommissioning industry. However as proven by Scintam Engineering’s previous work and use cases, the technology is also potentially applicable to the automotive, infrastructure, oil and gas and space sectors, among others.

“The RAISE project with CRADLE was a pleasure to be involved in. At Scintam, we have always wanted to promote our technology to the nuclear and other demanding environment sectors, but this is difficult as an SME. CRADLE has shown us what a diverse team of engineering and business minds, from industry and academia, can achieve in short development period. Each consortium member played to their own strengths – with Scintam providing the FastEDR portable EDM equipment – and the experts at CRADLE providing the know-how for integrating our system with the robotics, computer vision, and remote operation platforms. This is something that would have taken us 12 months+ to achieve in-house, but with CRADLE we were able to demonstrate the system to key industry players within 6-months from inception of the project. We are excited to see the follow-on from the showcase day and we hope to work with the CRADLE team to commercialise the platform.”

Sam Catchpole-Smith, CEO of Scintam Engineering Ltd.

This is a landmark achievement for CRADLE after its’ inception last year, to be tackling innovative industry challenges, and to have done so by forming a collaborative team consisting of colleagues from Amentum, The University of Manchester, and Scintam Engineering as a partner SME. After the success of this initial technology demonstration, CRADLE aims to continue development of this platform and work towards a fully integrated and deployment-ready solution, and to advance automation elements as far as would be suitable for a particular use case.